Originally published July 5, 2020 | Vinyl Community Discussion

Direct Metal Mastering and Direct-to-Disc—What's The Difference?

Originally published August 8, 2020|Vinyl Community Discussion

You may have noticed some vinyl records that feature labels or hype stickers that say DMM (Direct Metal Mastering) and others that say Direct-To-Disc. What are the differences, and what do these audiophile options mean for your listening experience?

Something to get straightened out at the outset, Direct-To-Disc and DMM aren't just buzzwords to sell records; however, they are considered more of a specification that describes how the album was prepared and made. But are these manufacturing processes audibly noticeable enough to make a difference? And is purchasing DMM and Direct-To-Disc vinyl records worth the additional cost? That is what we will discuss in this article.

The Traditional Record Manufacturing Process

To fully appreciate the benefits of DMM and Direct-To-Disc processes, we should briefly explain how records are traditionally made.

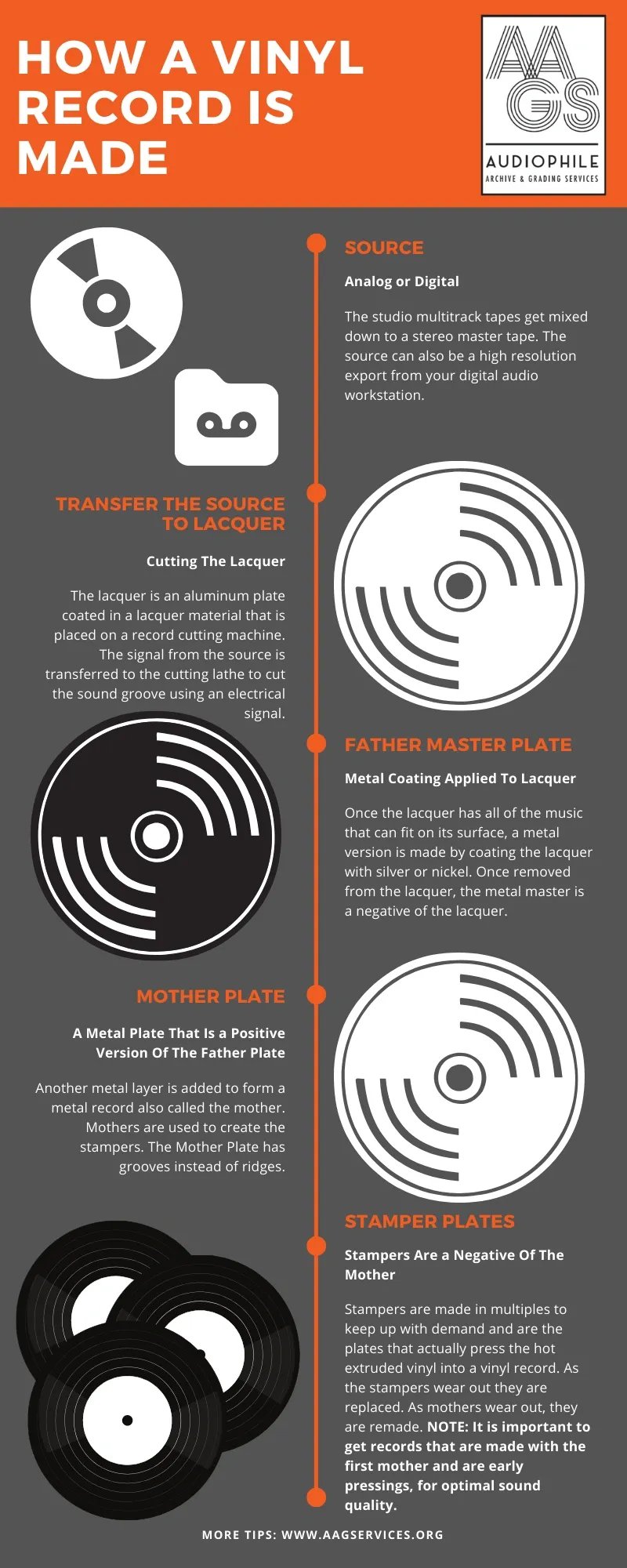

Commonly, when the recording studio finishes tracking a song, the multitrack tapes will get mixed down to a stereo master tape. The source can also be a high-resolution export from your digital audio workstation, but digital sources are no fun! I promise not to go down the analog vs. digital 'rabbit hole' in this article. We will save that discussion for another time.

The source, whatever it may be, is then transferred to the lacquer acetate. The lacquer is an aluminum plate coated in a lacquer material placed on a record cutting machine. The lacquer is turned on a cutting lathe, and the sound groove is etched with a special stylus suited for this task. The source signal is transferred to the cutting lathe to cut the sound groove using an electrical signal, in essence, vibrating the stylus to make the sound groove. Once the lacquer contains all of the music that can fit on its surface, the lacquer acetate goes through the galvanization process. A metal negative version of the lacquer is formed by coating the lacquer with silver or nickel. Once removed from the lacquer acetate, the metal master is a negative of the lacquer, meaning, instead of grooves, it has ridges. This metallic disc is called the Father Plate. Next, another metal layer is made from the Father Plate to form a positive metal record, also called the Mother Plate, featuring grooves instead of ridges. Mother Plates are used to produce the stampers. Stampers are the negative of the mother and are used to press the extruded vinyl material to make our vinyl records.

INFOGRAPHIC - How A Vinyl Record Is Made

Now that we know how records are commonly made, we will examine the differences between the conventional process, DMM, and Direct-To-Disc and what makes them special.

Direct Metal Mastering

Records manufactured with Direct Metal Mastering technology are usually marked by a "DMM" logo on the outer record sleeve. Many current production audiophile pressings and some standard production LPs from the 1990s only indicate its use by inscribing "DMM" in the lead-out groove area of the disc. But how is Direct Metal Mastering different from the conventional way records are made?

Instead of an aluminum plate coated in Lacquer acetate, Direct Metal Mastering starts with cutting the source directly to an uncoated copper plate. By cutting directly to the copper, the Father Plate process can be bypassed, in essence, making the copper master plate the Mother Plate. DMM thereby makes a three-step process a one-step process by creating the Mother Plate as the initial step and then making stampers from the copper plate.

The benefits of DMM is a much lower noise floor, and less surface noise because less steps are in the process. Because the source is cut into a hard metal surface instead of the soft lacquer acetate, it results in a more defined sound, preserving more high-frequency fidelity, and broader stereo imaging. Due to corporate acquisitions, DMM is now obsolete but is being supported by some pressing plants that are keeping the technology alive by maintaining the cutting lathes with parts units and self made parts.

The drawback of DMM is that any noise that is in the source, is still cut into the copper plate. This brings us to Direct-To-Disc technology.

Direct-To-Disc

Direct-To-Disc takes a different approach. The traditional record production process stays the same—Direct-To-Disc > Lacquer > Father > Mother > Stampers. However, the most significant difference is the source: no master tapes, and no digital files. The signal chain is as follows: Musician > Mixer Channel Strip > Cutting Lathe. No tape, no mastering, nothing. Many claim this recording method is the closest that we can get to the musician's live performance. There are drawbacks musically. 1. The musicians get no edits, overdubs, or breaks between songs for the 15 minutes of recording that side of the record, and if the instruments go out of tune, too bad! If someone makes a small mistake, oh well! Instead of rolling tape, your performance is cut in real-time to an expensive lacquer acetate disc. 2. No post-production. No mastering process. The mix is the mix is the mix.

The benefits though, are virtually silent pressings, gobs of dynamics, and fantastic imaging. Oh, and no tape hiss and an entirely analog recording.

While direct-to-disc was used on some folk and jazz recordings in the past, the Berlin Philharmonic recognizes its benefits with classical recordings. The Anton Bruckner Symphony #7, The Berlin Philharmonic, conducted by Bernard Haitink, was incredibly captured with this direct-to-disc performance that it makes you feel like you're in the seat at the concert hall. A review of this release is coming to aagservice.org shortly.

Conclusion

Both DMM and direct-to-disc processes sound great and are both not common compared to the traditional method to pump out the most amount of records. Also, in the modern age, high-resolution digital sources are getting better, and for the all-analog hounds out there (I'm one of them), the tape formula, and tape machines are getting quieter. However, some releases sound fantastic in their DMM or direct-to-disc counterparts and are worth listening to if you come across the opportunity to pick some of those titles up.

If you are interested in vinyl record encapsulation or any of our other services, please visit us at aagservices.org to learn more about how you can bring your collection to the next level! info@aagservices.org